Hydraulic cutting machines use a pressurized hydraulic fluid to power a blade that slices through various materials. They are an essential tool for manufacturing, construction, and metalworking professionals. However, they can be expensive.

When choosing a hydraulic cutting machine, consider the manufacturer’s reputation, production capacity, quality control, certification, and after-sales service. These factors can help you find the right model for your business.

Safety measures

Hydraulic cutting machines are widely used in the automotive industry to cut and shape metal sheets for car bodies and parts. They are also used in the construction industry to create plumbing fixtures and other building materials. However, these machines can pose a safety risk when improperly operated. Therefore, it is important for employees to follow the proper safety measures when operating these machines.

One important factor to consider when choosing a hydraulic cutting machine is its capacity. This refers to the amount of material it can cut in a given timeframe. A high-capacity hydraulic cutting machine can help increase productivity and save time.

Another factor to consider is the machine’s accuracy. A good hydraulic cutting machine should be accurate and provide precise cuts, ensuring consistent results. It should also be easy to use and offer a user-friendly design. In addition, a hydraulic cutting machine should be affordable and have a long life. In summary, businesses should choose a manufacturer that has a good reputation and can meet their specific business requirements.

Operation

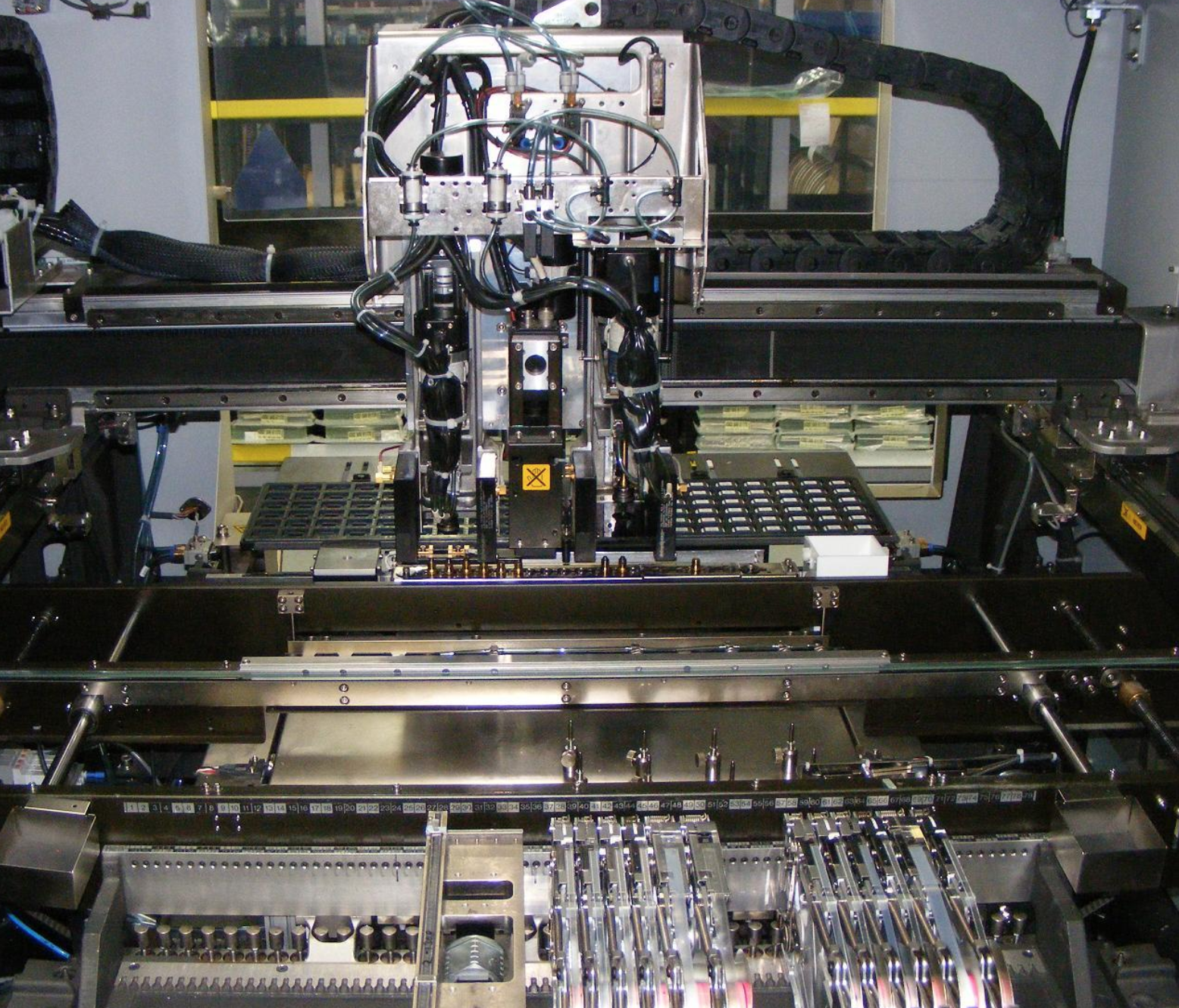

The first step in operating a hydraulic cutting machine is to select the correct tool for the job. This may include a variety of blades and cutters designed to work with different materials. The next step is to activate the system, which pressurizes the hydraulic fluid and powers the cutting tool. The hydraulic system is controlled by the control circuit, which primarily connects solenoid valve and oil pressure, based on operating instructions, to drive the blade carrier’s up-and-down movement and ultimately achieve the desired cut goal.

The hydraulic system operates at high temperature and pressure, so it’s important to use anti-wear hydraulic oil with a viscosity rating of ISO VG46# or higher. The hydraulic oil should be filtered regularly to prevent contaminants from damaging the equipment.

When choosing a hydraulic cutting machine, consider its power capacity, accuracy, and safety features. It should also be affordable and offer good value for money. Be wary of cheap machines, as they may not offer the quality or longevity you need.

Maintenance

A hydraulic cutting machine requires regular maintenance to function properly. This includes lubrication and cleaning of the machine after every use. Performing these tasks can help reduce the risk of accidents and prolong the lifespan of the machine. It is also important to keep the power supply clean and properly insulated.

A standard sized hydraulic cutterhead can cut round bar, wire strand, and cables. Its guillotine action cuts materials quickly and precisely. It is simple to operate and is safer than other guillotine cutting methods. A hydraulic cutterhead can also be used to remove seized nuts, and it is available in different sizes to suit various applications.

A hydraulic cutting machine should only be operated by a designated person. It is forbidden to reach into the machine or pick up material by hand during operation. If there is an abnormal noise or any other dangerous situation discovered during operation, the machine should be stopped and the issue resolved before it can resume operations.

Replacement parts

There are many parts available for your hydraulic shearing machine. Some of these are in stock, while others need to be custom made and manufactured. You can find replacement shear parts from various online sources. These parts include hydraulic cylinders, shear dies and punches, rams, moving platesns, clevises, trunnions, mechanical drives, electrical systems, hydraulic seals, lubrication systems and more.

Kiefer Tool repairs and rebuilds equipment for manufacturing companies across the Midwest, Middle Atlantic and portions of the Northeast. Our services also extend to metal cutting machines, including hydraulic presses. We can help you get the most out of your machinery.

Antraquip is dedicated to keeping spare parts in stock at one of their locations in the USA to ensure minimal downtime for any equipment that they supply. In addition to offering replacement parts, Antraquip offers used equipment search and brokering services, machine rebuilds, and engineering solutions. The company is also known for its free equipment consultations, and provides a variety of service programs, such as maintenance contracts and onsite training.