The size of screws is a vital part of the materials that they hold together. This is why it can be confusing when different manufacturers use different nomenclatures for the same screw sizes.

Fortunately, there are some common characteristics that all screw sizes have. The callout on a box of screws will usually include the major diameter, the threads per inch, and the screw length. It will also include a tolerance class and LH symbol (if needed).

Diameter

When choosing the length of a screw, it is important to take into account the thickness of the material that the screw will be threaded into. If the screw is too long, it can protrude through the material and cause damage. It also can become a tripping hazard for the user and can be dangerous.

There is a correlation between the head diameter and gauge (imperial). This is due to the fact that from screw gauge 6 onwards the head size is roughly twice the diameter.

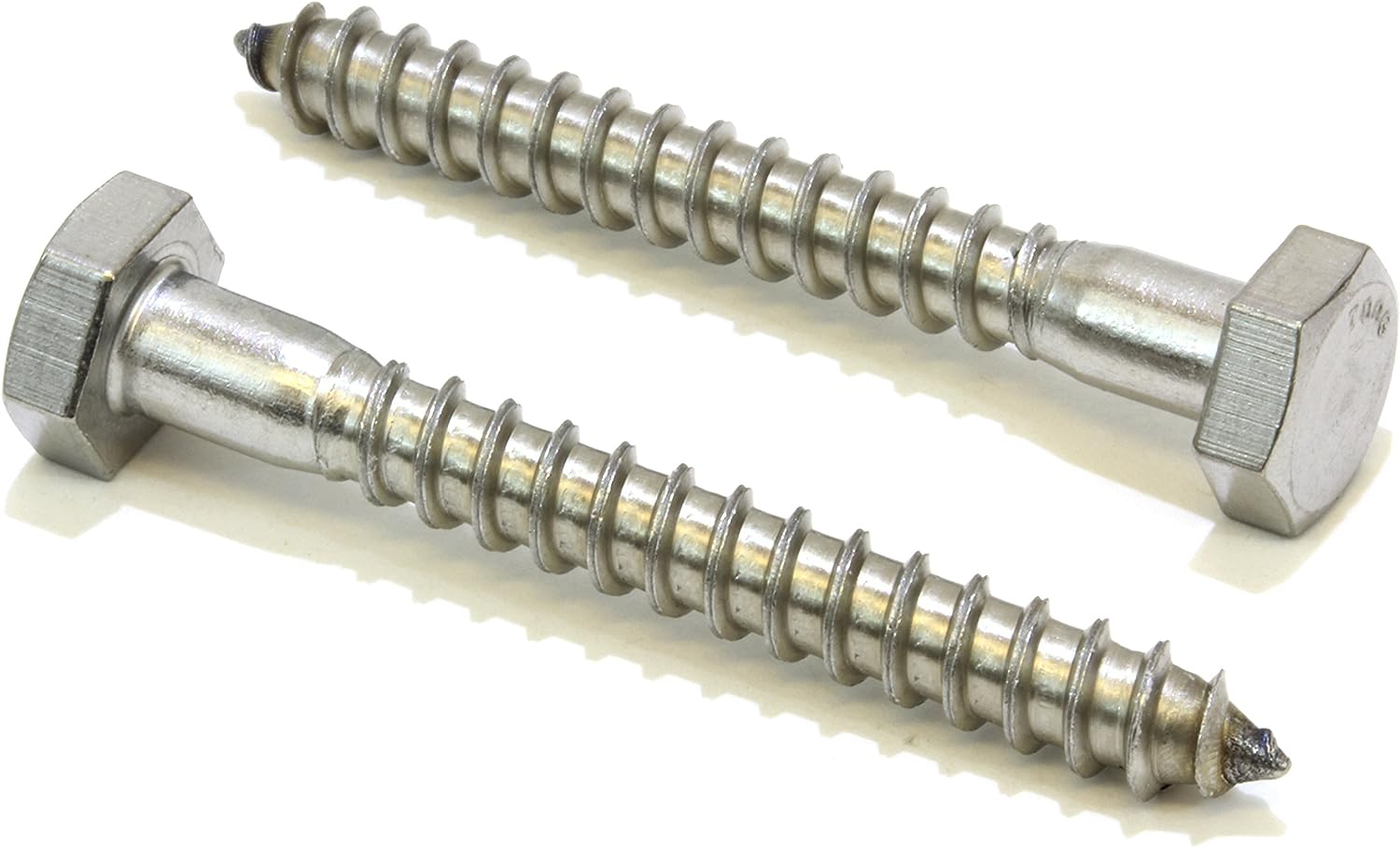

The screw length is measured from the point beneath the head. Some screws, such as truss-, round-, and hex-head screws, do not go all the way into the surface. These are known as non-countersinking screws. The length is also specified in the callout on a box of screws.

Pitch

Pitch is a property of sounds that allows them to be ordered on a frequency-related scale. High frequencies are perceived as a higher pitch, while low frequencies have a lower one. Pitch is also a perceptual attribute of a musical note, and it can be determined by listening to the sound and seeing how high or low it sounds.

Screw sizes are categorized by their major diameter and thread pitch. In the United States, this information is usually found on a screw label with a callout number. While finding the major diameter is straightforward, determining thread pitch can be more challenging due to its minute spacing. For this reason, you may need a digital caliper to help you with this task. However, this step is important for ensuring that you get the right screw for your project.

Length

The head diameter of a screw is approximately double the gauge (imperial). However, it is difficult to accurately predict the head size of a screw from the outside diameter and gauge alone.

In metric systems, it is more straightforward because you measure the major diameter and threads per inch in mm, not inches. The thread pitch is easily determined by counting the number of peaks in a one-inch section of the screw. You can also find this information on a screw or bolt callout. However, the length of a screw is specified from beneath the head to the tip. Many screws have flat heads that can be driven flush with a surface, such as pan head, countersunk or hex screw, while others protrude above the surface, such as round, truss and button head screws.

Tolerance class

The tolerance class is the difference between the maximum and minimum size limits of a part. It is usually given in a GD&T table. It can be difficult to understand at first, but it will help you communicate tolerance requirements clearly. The lower deviation indicates how much smaller the measurement can be, while the upper deviation indicates how much larger it can be.

Metric thread tolerances are indicated by capital letters and lower-case letters. The letter H describes a tolerance with zero deviation from the theoretical basic profile of a screw thread, and G and h describe tolerances with deviation above or below the basic profile.

The letters are then combined with the IT grade and tolerance position to establish the tolerance class. For example, a screw thread designation of M12 x 1 has a tolerance class of 6H for the nut and 5g for the pitch diameter.

LH symbol

Some screw threads are left-handed and need a special symbol to indicate this. This symbol is usually included after the class of fit (A for external and B for internal) and the lead and pitch.

When it comes to the screw length, the callout on the box will also include the screw head diameter and the screw shaft length. The latter is important because some screws, such as hex or button-head screws, don’t extend all the way into the hole they’re installed in.

Understanding the various numbers in a screw size chart can be confusing at first, but once you know what they stand for it’s much easier to use them correctly. Keep in mind that there are several different labeling systems used throughout the world, so make sure you understand what a screw’s callout refers to before you start working with it.